3DMP

three-dimensional

metal printing system

Categories

Machine / 3D Printer

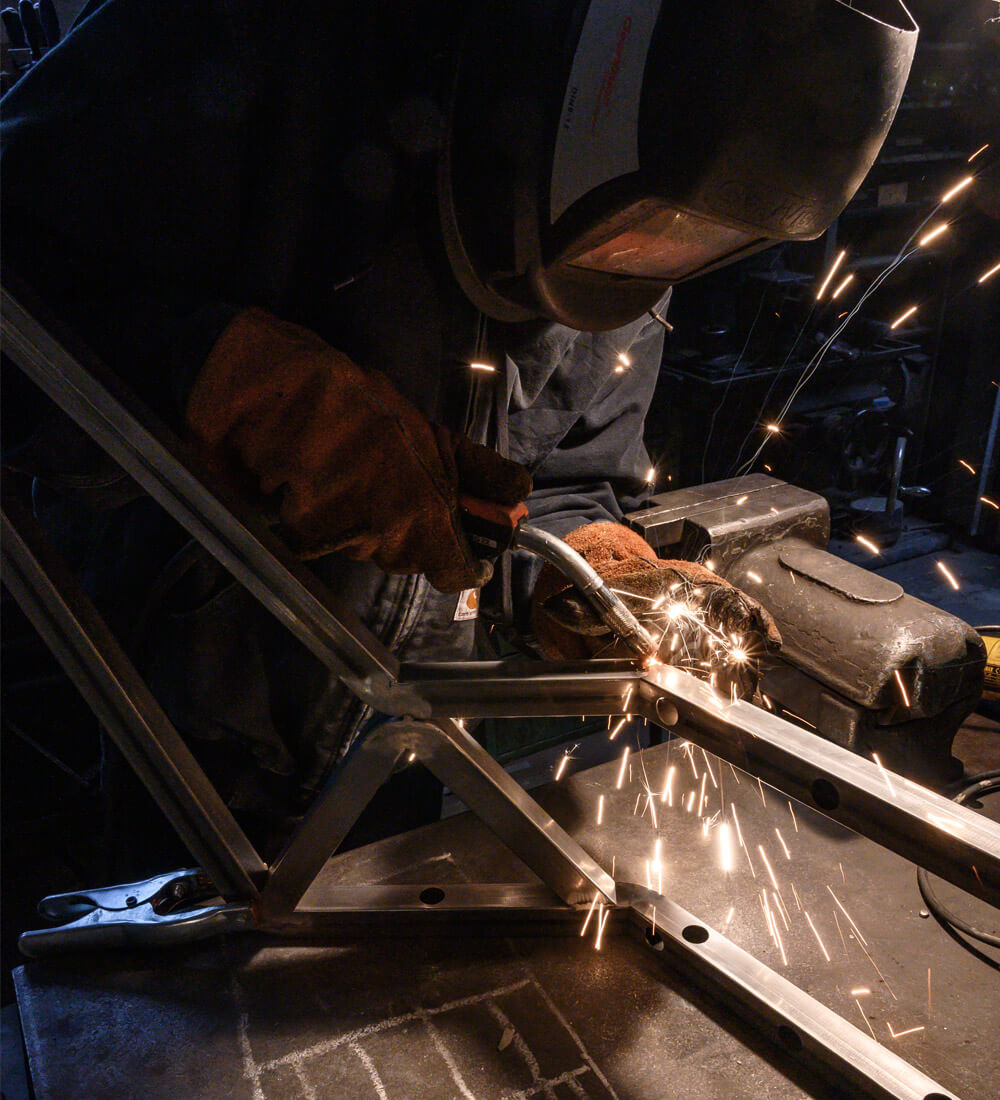

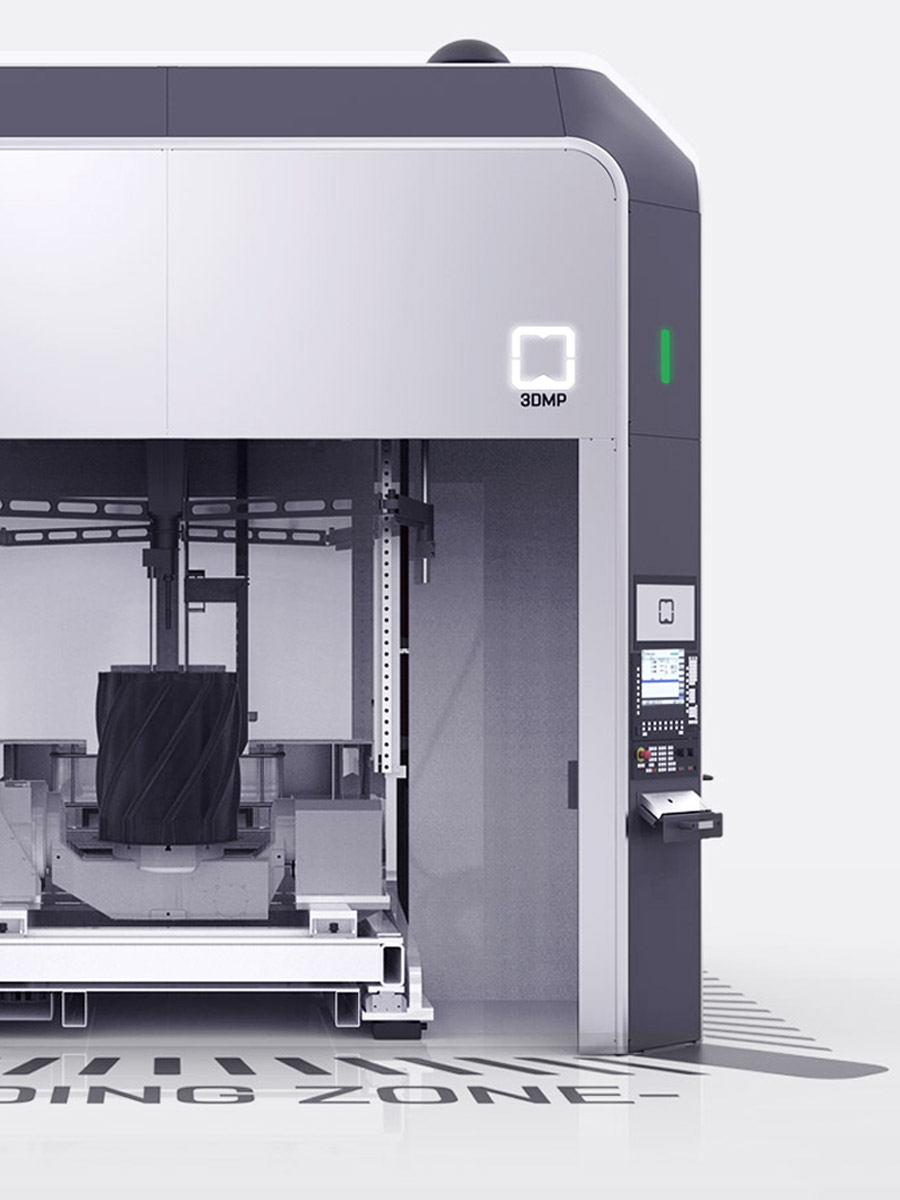

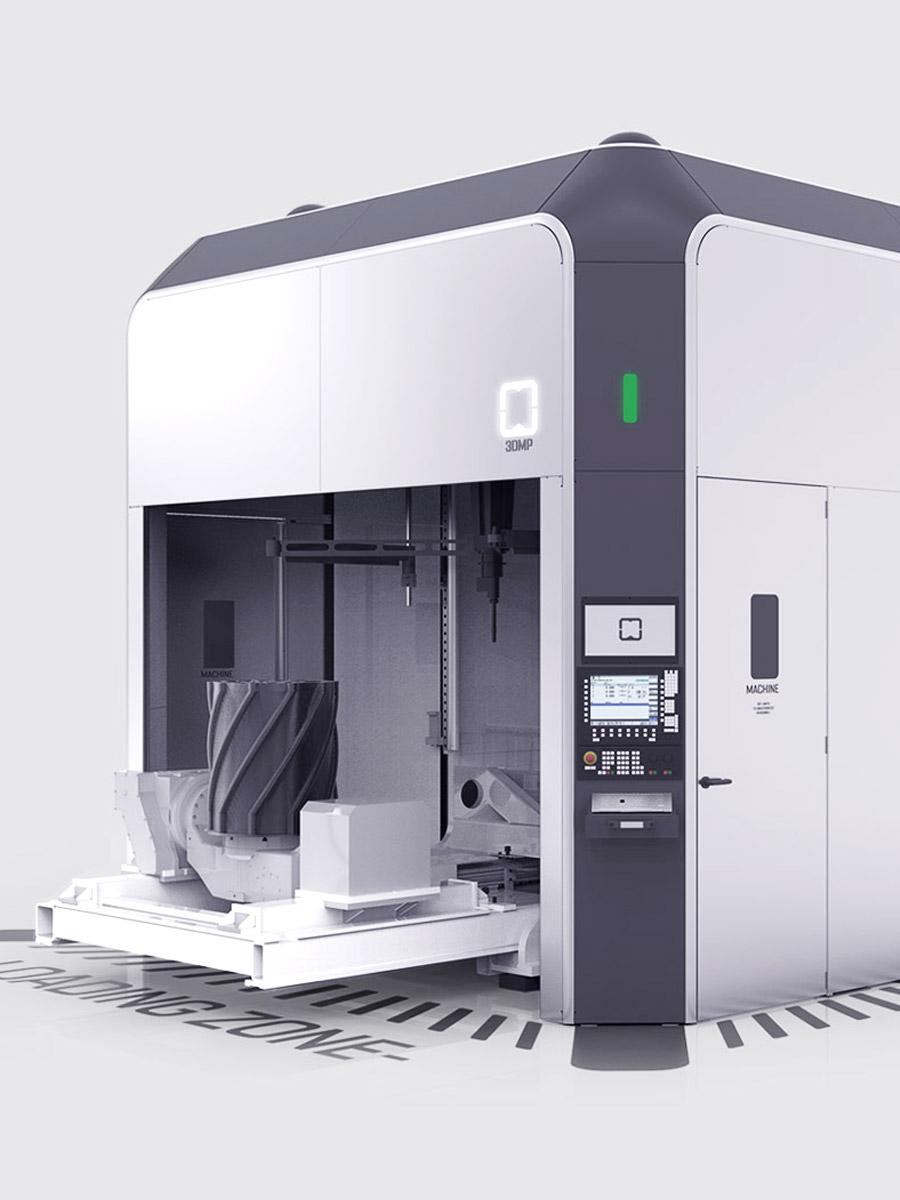

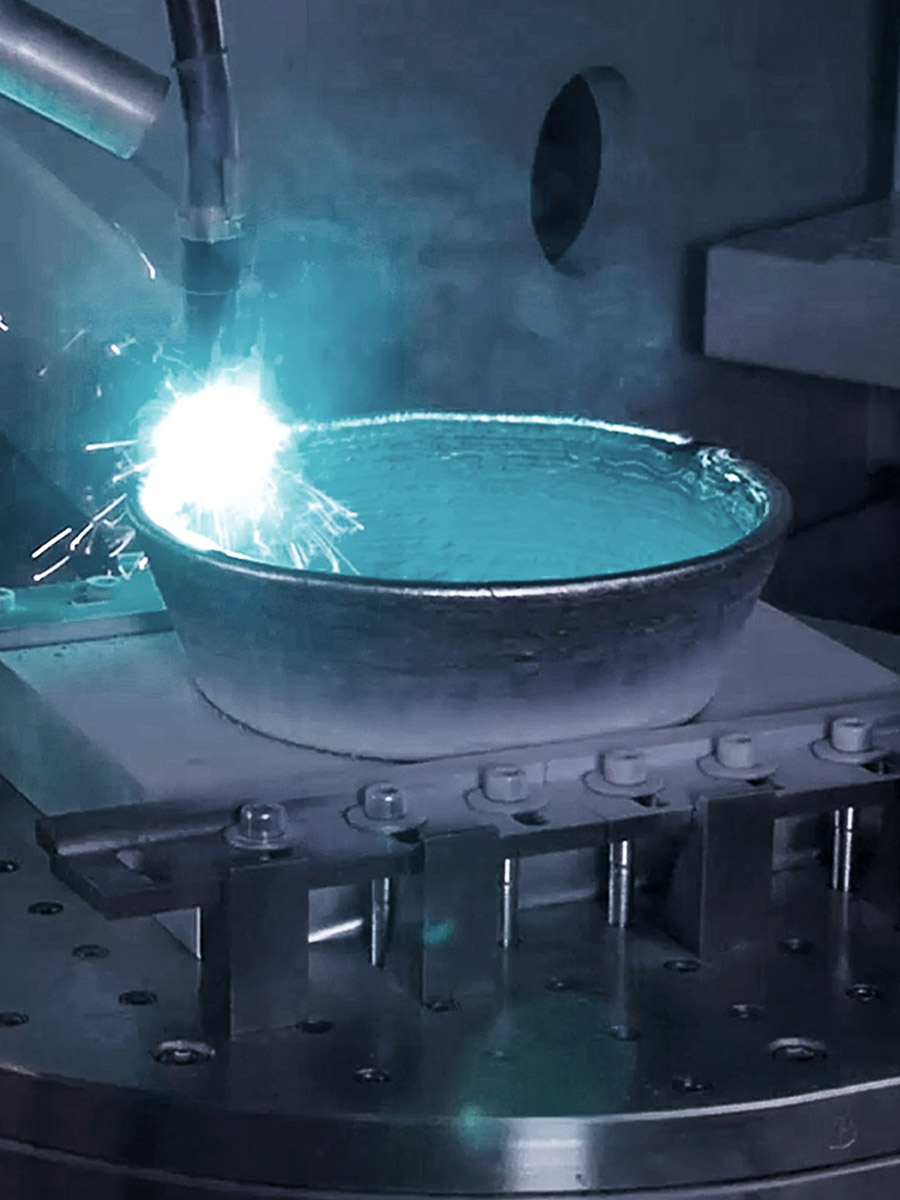

The GTarc-series combines the sophisticated process of arc welding and the CAD-models of the engineers in a completely new production-unit. The 3 or 5 motion axis guarantee a maximum of flexibility concerning the part volume and make the additive manufacturing of high quality metal parts.

The optional integrated milling unit makes an immediate finishing of the part possible. The by SIEMENS developed control unit for tooling machines is a synonym for an easy handling by using a very well-known system.

During the development and the construction of the GTar-series these two targets were always the basic requirements: – Easy implementation into the customer’s production process – Simple operability of the machines

Length

4.000 mm

Width

4.000 mm

Heigth

4.000 mm

Material

steel

aluminium

Colors

light grey anthracite

Technical Details

Process monitoring via camera

Machine access at ground level with a sliding working table for easy loading and unloading by crane

Actively cooled base plate

Soundproof housing

Integrated case ventilation and welding fume extraction

User-friendly control unit

High-end components of well-known manufacturers

Optional equipment

Temperature tracking by integrated Sensortherm pyrometer

GTarc cooling system for local cooling by cooling gas

Automatic welding torch cleaning system

Water-cooled inert gas cover for oxygen-sensitive materials

Additional information

about this product at

www.gefertec.de

about this product at

www.gefertec.de